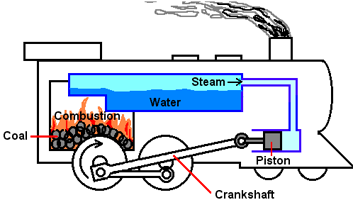

Steam Process

When heated, water turns as steam, as the amount of water expands as it turns to steam inside the boiler, creating a high pressure. The expansion of steam pushes the pistons that connect to the driving wheels that operate the locomotive.

1. Coal or oil are the fuels used for heating the water. Coal is carried to the firebox. Water is carried in the tender in a tank surrounding the coal by the injector.

2. The hot gases released from the coal flow forward through a series of flues or tubes to the front of the locomotive.

3. Heat turns the water to steam, and rises to the top of the boiler by tubes called the "steam generator" of the locomotive.

4. Steam elevates to the highest point in the boiler and the throttle is used to regulate the amount of steam being sent to the pistons.

5. Steam passes to the piston valves and to the cylinders. Once in the piston, the steam expands, pushing it in the opposite direction. At the end of the piston stroke, an exhaust port opens, allowing the steam to escape. Then the process is reversed with steam admitted to either side of the piston so that it is always under power. A lever in the cab allows the engineer to control the action of the piston valves (direction of locomotive movement, and timing).

6. The pistons push or pull the rods connected to the drive wheels, providing the force needed to move the locomotive.

7. The steam is exhausted through a nozzle and up through the smokebox into the stack. A draft or vacuum introduces air through the firebox grates to induce combustion of the coal. Both exhausted steam and coal smoke travel up through the stack.